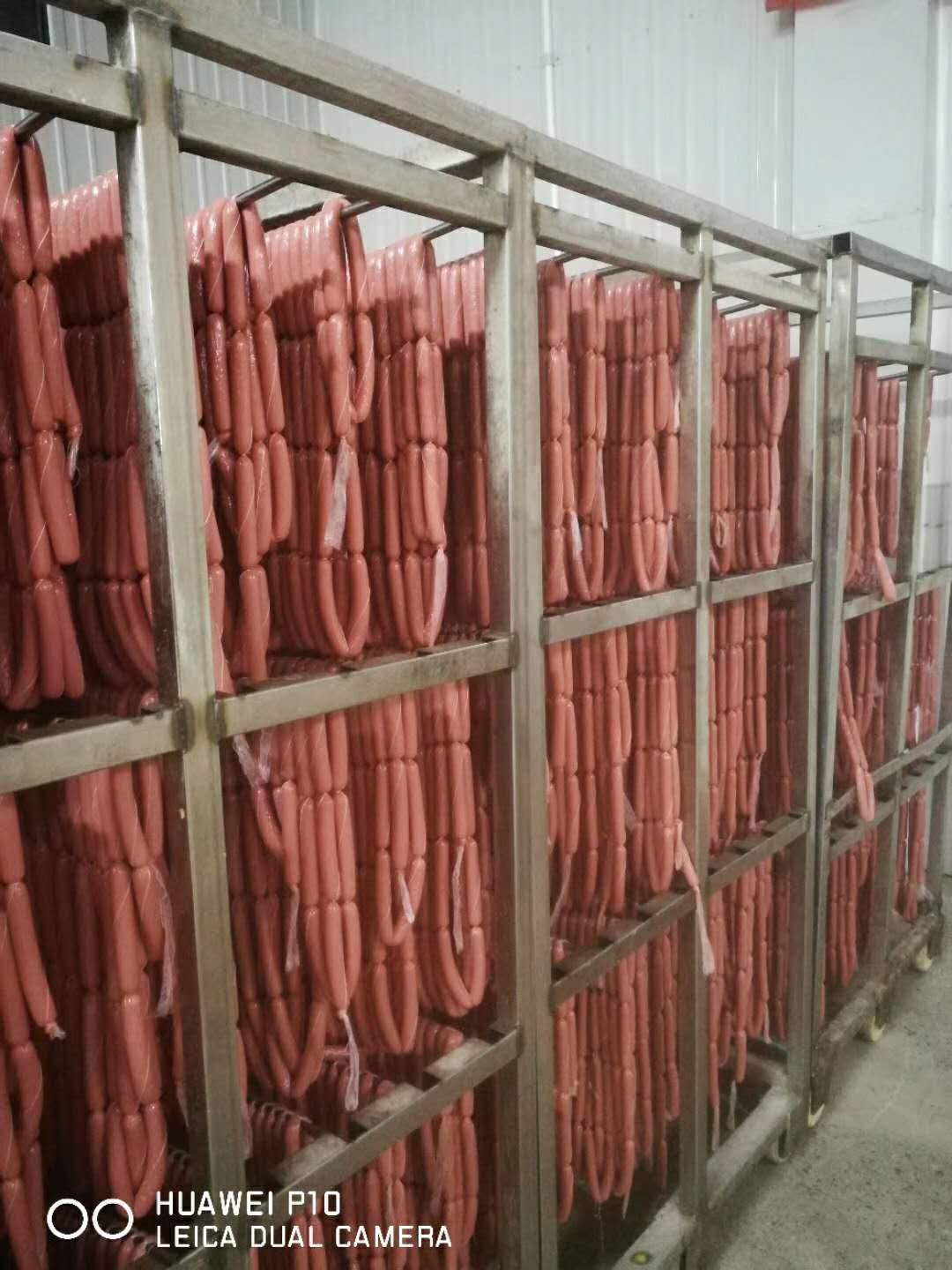

plastic quick peel smoke type sausage casings

plastic quick peel smoke type sausage casings

Product Title

Product Title

Parameters | Value iPeel/ iPeel-Gut (Chereva) | Unit measure | Test method | Test conditions |

Thickness |

18.0 (±2)/ 20.0 (±3) |

μm |

| Schroeder ball pad thickness gauge, Т=23˚С, RH=65% |

Temperature range of use | from - 40 to + 100 |

˚С |

- |

- |

Water vapor transmission rate |

400 – 700/ 450-700 |

g/m² х 24 hrs |

based on DIN 53122-74 |

At Т=30˚С, RH=90% |

Tensile Strength |

longitudinal 15-22/ 14-20 transversal 15-22/ 16-23 |

kgf/mm² |

GOST 14236-81 (ST SEV 1490-79) | Schimazu AGS-H test machine, V=100 mm/min, Т=23˚С, RH=65% |

Elongation at break

|

longitudinal 120-220/ 120-230 transversal 90-190/ 80-150 |

% |

GOST 14236-81 (ST SEV 1490-79) | Schimazu AGS-H test machine, V=100 mm/min, Т=23˚С, RH=65% |

Allowed tolerance for tube width, not more than |

(±2) / (±3) |

% |

| Electronic control system |

2.2. Advantages of the casing

2.2.1. Removal of the casing by peelers. The iPeel casing is made by a proprietary technology, and its properties make it possible to remove the casing off the finished product by means of automatic peelers.

2.2.2 Optimal adhesion of the iPeel casing to various types of sausage meat recipes provides for easy removal of the casing (type A, type R) off the finished product by means of automatic peelers; at the same time the casing adequately protects the finished product (festoons) during the storage.

2.2.3 High permeability of the casing to smoke and water vapor makes it possible for you to perform dry-heating and smoking processes which impart traditional taste of smoke and flavor to the products. This enables to obtain products with traditional sensory characteristics typical of products manufactured in cellulose, collagen, and natural casings. This also contributes to formation of a dense coagulated protein crust with a glossy surface of the product under the casing, which provides for consistent removal of the casing off the finished product without damaging the surface layer of coagulated protein (crust).

2.2.4 Extended range of products. The iPeel casing is supplied straight or ring-shaped, which extends the range of products by diversification of their appearance. The ring-shaped version of the iPeel casing makes it possible to supply products in the shape of half rings, without the use of expensive natural or collagen casings, and to remove the casing by peelers.

2.2.5 High heat resistance of the polymers used for production of iPeel casing significantly extends the temperature application range for the casing in comparison with collagen and cellulose casings.

2.2.6. High mechanical strength of the iPeel casing enables to stuff meat products by using various types of filling equipment while keeping production speed high as well as reaching a

6-8% overstuffing caliber compared to the casing’s nominal caliber. Caliber accuracy of iPeel casing plays a significant role in stable stuffing on modern high-speed automated filling systems and fillers with a twisting device.

2.2.7. Microbiological resistance. The materials used for production of the iPeel casings are inert to the action of bacteria and mold fungi. This improves the hygienic characteristics of both the casing itself, and the finished products.

2.2.8. Optimal oxygen and water vapor transmission rate compared with collagen and cellulose casings at the finished product storage temperatures (+2…+6 ºС) provide for the following advantages:

- reduction of oxidation processes in the finished products;

- better preservation of the smoked flavor and aroma in the finished products until removal of the casing by means of a peeler, and throughout the shelf life of the product (festoon)

- reduced weight losses (≈ 2 – 5%) during the storage (it is recommended to keep the

products in Modified Atmosphere Packaging (MAP) and vacuum packed);

- Deceleration of syneresis process (separation of liquid) inside end-products packed into vacuum packaging (≈ less than 1.5 – 2 times).