Smoke Permeable Plastic Sausage Casings Curved Rings

- DALONG

- DALIAN

- 30 days

- 1 container/month

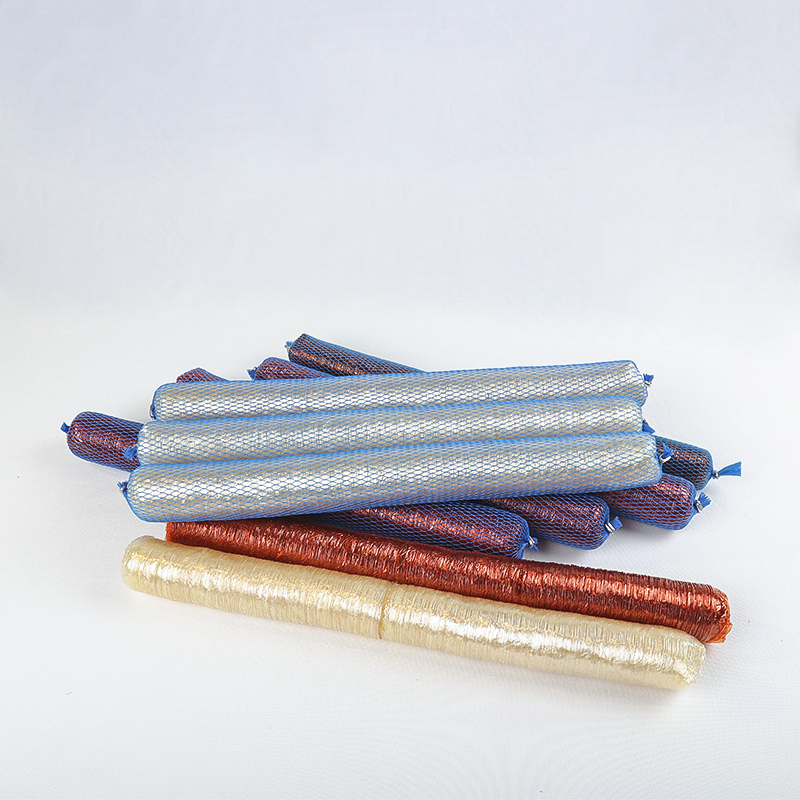

Smoke Permeable Plastic Sausage Casings Curved Rings is one type smokable plastic sausage casings,

it slowed the smoke permeable into the sausage and make it with smoke flavor,

the casings surface wrinkle and similar as nature casings.

Product smoke sausage casings

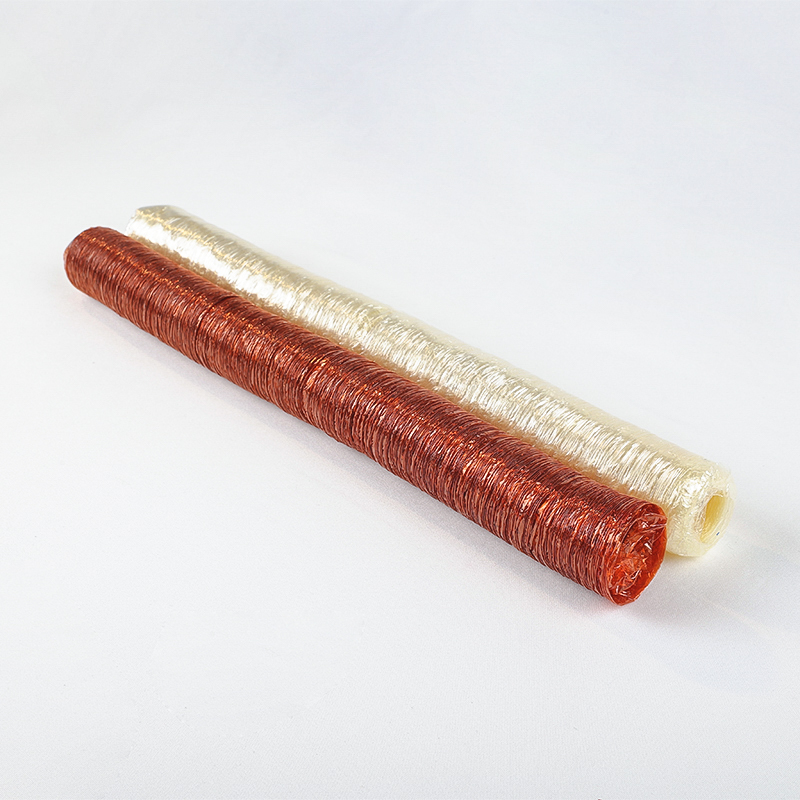

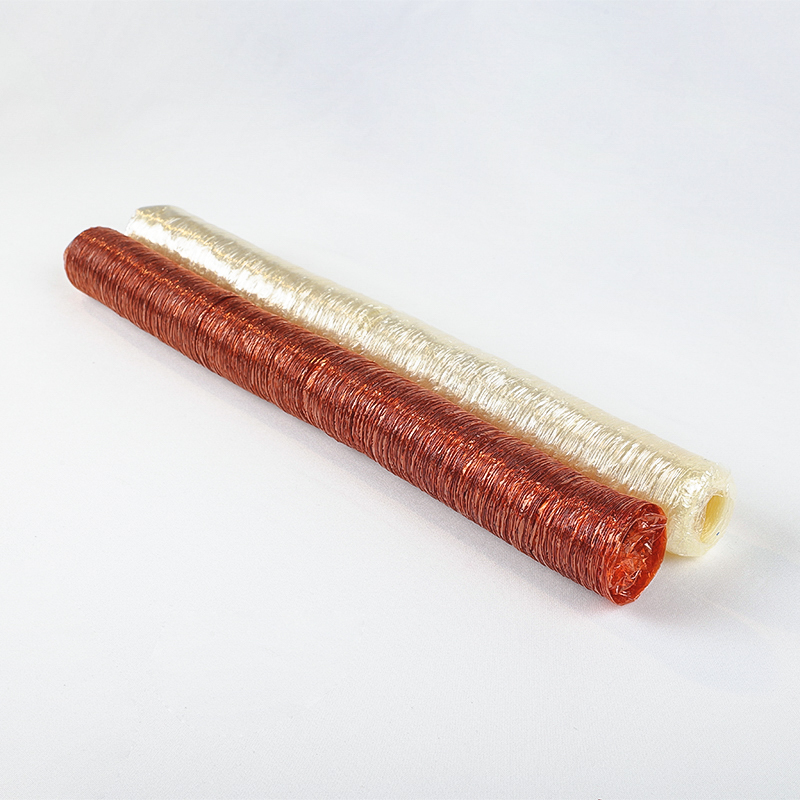

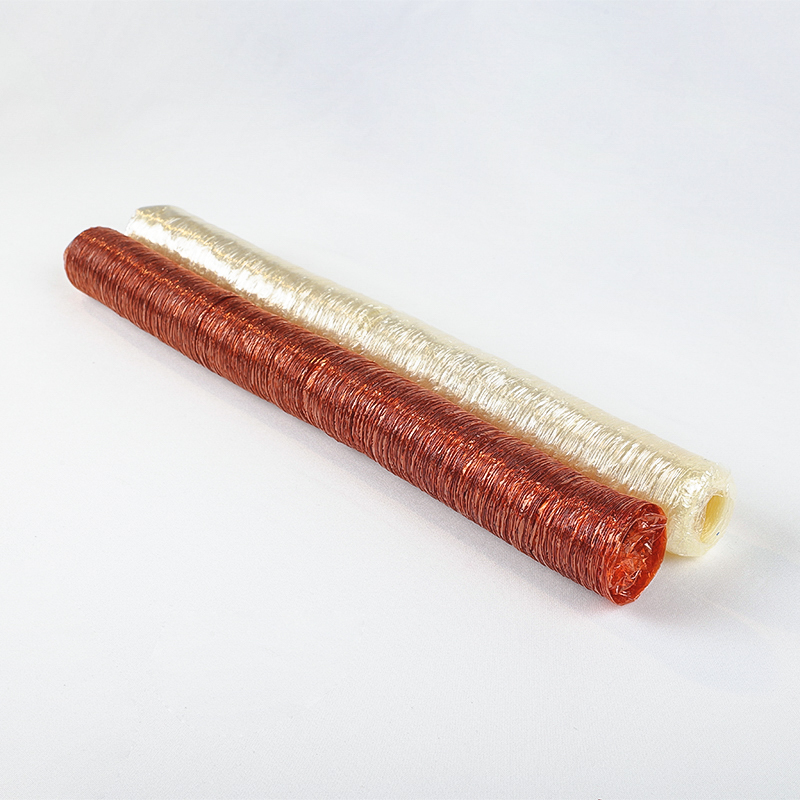

Natural color smoke plastic casings

it is natural color plastic smoke permeable type casings. it is used for producing the curved rings sausage with smoked flavor. when smoked the sausage, there will be little holes from the casings and let the smoke permeable into the sausage.

After smoking, the surface of the sausage will be wrinkle and looks like as natural casings of hog casings or sheept casings.

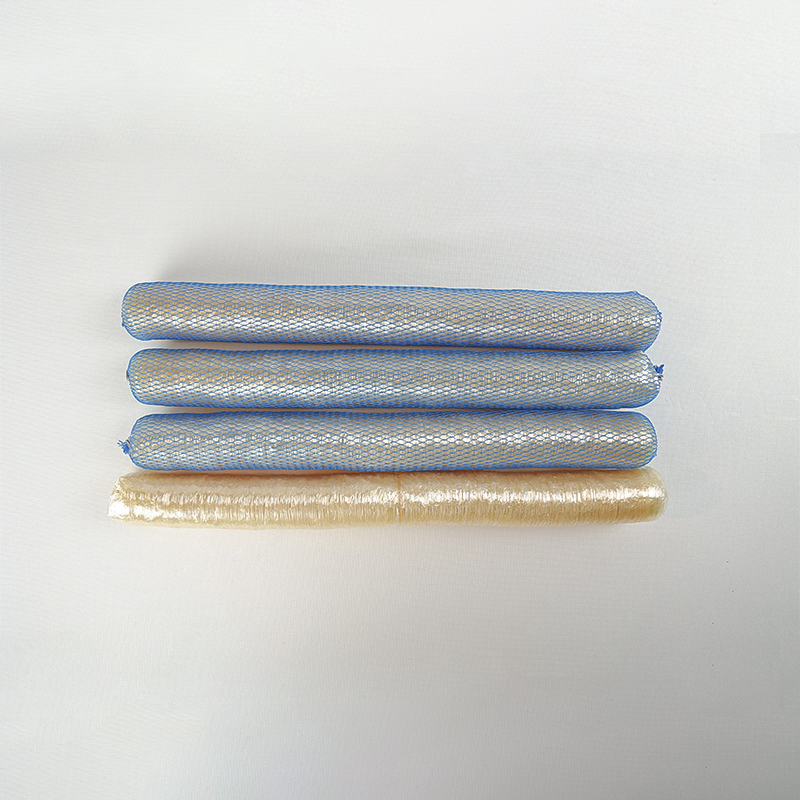

the casings are shirred in sticks, 30 meters/stick. smoke permeable casings

and the material of plastic casings are polyamide.

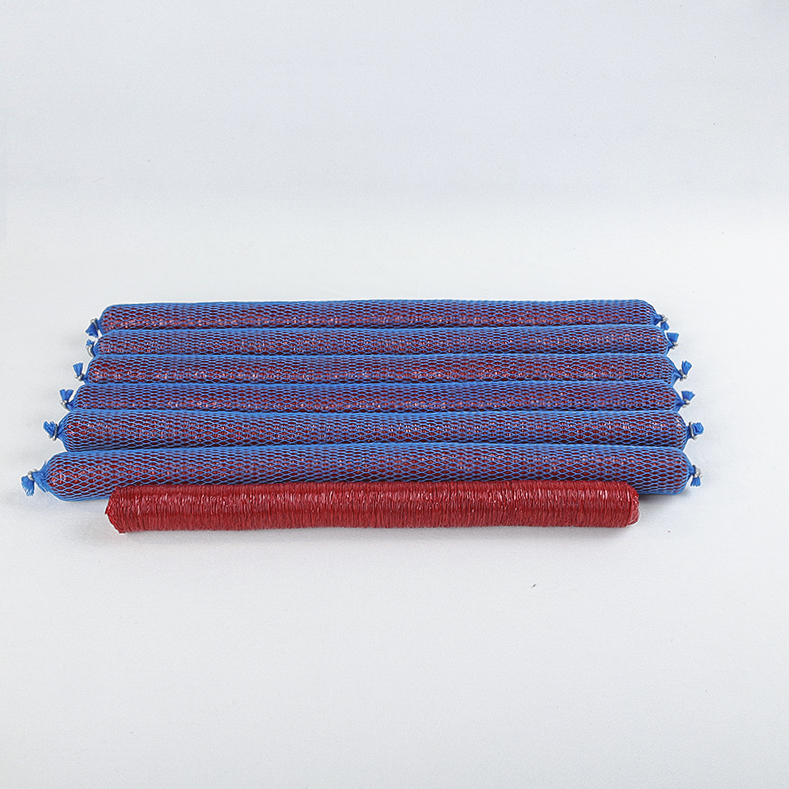

smoke color plastic sausage casings

It is designed for the customer who make their sausage with smoked color as natural casings. the casings are with smoked color, after smoking, the sausage casings will look similar as hog casings, and the surface of the sausage skin will be wrinkled.

also the sausage are in ring shape.

compare with natural casings, it is much more healthy and cost less,also it will let the sausage with longer shelf life, also not loss weight for a longer time.

| Product | Smoke Permeable Plastic Sausage Casings Curved Rings |

| color | transparent or clear smoke sausage casings |

| function | smoke flavor permeable into the sausage |

smoke sausage casings

polyamide sausage casings

nylon sausage casings

About Us smoke sausage casings/smoke permeable casings

Dalian Dalong Plastic Packaging Co.,Ltd located in Dalian of China and established since 1990, for years development, we had reaserched and produced five layers high barrier plastic sausage casings, it can be colored or printing, in rolls or shirred, and plastic quick peel off sausage casings instead of cellulose casings, with little calibers hot sale for transparent or red color. Thailand Vietnamese sausage casings ,Korean rice sausage casings, forzon meat sausage casings, smoked permeable plastic sausage casings smoke sausage casings ,smoke permeable casings,plastic sausage casings

Our smoke permeable casings large export to South Korea, Malaysia, Philippines, Vietnam Colombia, Mongolia, America, Canada etc Countries. Each year over 40 containers.

plastic casings in 20ft smoke permeable casings

smoke permeable casings

Cooling and removal of the smoke sausage casings

Removal of the smoke sausage casings/smoke permeable casings is done by the producers, as a rule, on the next day after manufacture of the frankfurters. In that case cooling of the products is made under the standard conditions for products intended for storage in casing (see 4.6 above).

Casing can be removed on the day of manufacture. In such case, after water cooling (showering) the products must be cooled in a cold store during 3-6 hours, depending on the diameter of the products. The recommended product core temperature is 10-12 ºС. Exclude any exposure of the finished products to air drafts (fast-moving air flows) during the storage, because this leads to accelerated evaporation of moisture from the product surface and may cause wrinkles on the surface.

Immediately before removal of the casing, shower the products with cold water again during 10-15 minutes.

Peelers are provided with replacement sets for different product diameters; install the required set according to the recommendations of the equipment manufacturer. It is recommended to use a smooth vacuum roller (without knurling).

In the process of removal of the casing, supply steam to the steam pipe of the peeler.

Immediately before putting of a festoon of products into the steam pipe of the peeler, remove the knots from the ends of the festoon to exclude the knots getting into the vacuum roller holes, which may result in winding of the casing onto the vacuum roller.

The pressure rollers of the peeler must be adjusted depending on the diameter of the product. The roller pressure must maintain the required contact with the product for a free and stable (without slipping) transport of the festoon to the casing incision area, without damaging the product.

Provide for a free passing of the festoon of products through the steam pipe, without the festoon looping or knotting.

The peeler speed must be adjusted on a case-by-case basis, depending on the length, diameter, and shape of the products. The greater the diameter and length of the product, the less should be the peeler speed.

The knife’s blade should be adjusted for a stable cut of the casing, with a minimal depth of incision.

Adjust the supply of compressed air to open the casing after incision. The compressed air flow should consistently open the cut casing, without damaging the protein crust on the product.plastic sausage casings